1. A na-emekarị ihe ndọta neodymium site na ntụ ntụ nke neodymium, ígwè, na boron nke a na-ejikọta ọnụ n'okpuru nnukwu okpomọkụ na nrụgide iji mepụta ngwaahịa emechara.

2. A na-etinye ngwakọta ntụ ntụ n'ime ihe ebu ma ọ bụ akpa ma kpoo ọkụ na okpomọkụ dị elu nke mere na ọ malitere ịgbaze na fuse.

3. Ozugbo ihe ahụ rutere n'ebe na-agbaze ya, a na-ejide ya na okpomọkụ a ruo oge ruo mgbe ọ na-esiwanye ike n'otu akụkụ na-enweghị oghere ma ọ bụ mgbawa n'etiti ihe.

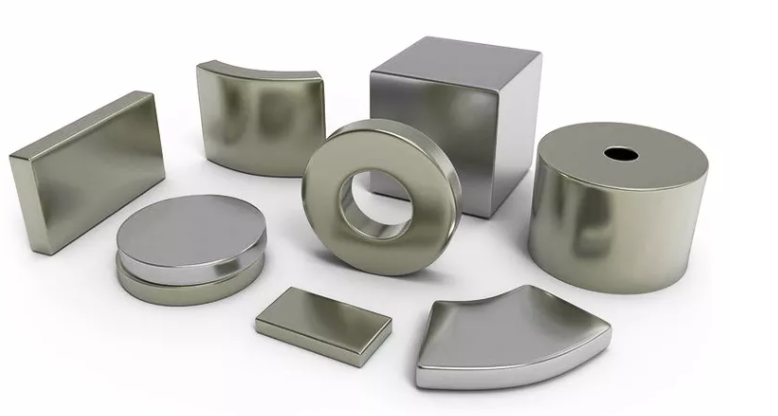

4. Mgbe emechara ihe siri ike, magnet nwere ike ịmegharị ya n'ụdị na nha ya chọrọ site na iji ngwaọrụ dị iche iche dị ka igwe igwe ma ọ bụ lathes dabere na ngwa ngwa.

5. N'ọnụ nke magnet nwere ike na-egbu maramara nke ọma ma ọ bụrụ na ọchọrọ tupu e kpuchie ya na nchebe plating dị ka nickel ma ọ bụ zinc maka corrosion eguzogide nzube.

Nhazi nkọwa ndị ọzọ, biko jiri obiọma hụ eserese dị n'okpuru:

| Mba. | Usoro Usoro | Nzọụkwụ mmepụta | Ọrụ teknụzụ |

| 1 | Nyocha ihe akụrụngwa | 1.ICP-2.chemical Analysis-3.Analyser(C&S) | Nchọpụta Rohs Nnwale ihe mejupụtara Nyocha ịdị ọcha |

| 2 | Ọgwụgwọ mbụ nke akụrụngwa | 4.Swing- 5. ihicha- 6.Mmetụta ihicha | Ịkụ ígwè Ikuku ikuku na-ekpo ọkụ Mmetụta ihicha |

| 3 | Njikwa Efrata | 7.Ingredient Control | tụọ Batching Gwakọta Ngwakọta Raw |

| 4 | Nkedo nkedo | 8.Vacuumizing-9.Melting-10.Nkedo | Na-ekpochapụ ihe Na-agbaze Na-agbaze Nkedo |

| 5 | Mbelata nke hydrogen | 11.Pre-treating-12.Vacuumizing-13.Tinye hydrogen | Tupu ọgwụgwọ Na-ekpochapụ ihe Hydrogen kwatuo |

| 6 | Ịgba igwe | 14.Shattering-15.Egwe-16.Jet Mill-17.Granularity Control | Na-agbaji Na-egweri Jet Mill Nleba Rogular |

| 7 | Na ịpị | 18. Ntụ ntụ ntụ -19.Pre-pịa - 20.Pressing -21. Isostatic ịpị | Ntụ ntụ ntụ Tupu ịpịnye Na ịpị Isostatic ịpị |

| 8 | Na-egwu egwu | 22.Vacuumizing- 23.Sintering -24 ọgwụgwọ okpomọkụ | Na-ekpochapụ ihe Na-egwu egwu Ọgwụgwọ okpomọkụ |

| 9 | Nyocha | 25.BH eriri-26. PCT-27. Nnwale njupụta -28.Roughcast Nyocha | Nleta magnetik Nnwale ọnụọgụ okpomọkụ PCT Ntụle njupụta Nyocha |

| 10 | Ịrụ igwe | 29.Egweri -30.Iji gbue-31.Iji agụba | Na-egweri Ịcha waya Mbelata agụba ime |

| 11 | QC sample ule | 32.QC nlele ule | QC sample ule |

| 12 | Na-eme mkpọtụ | 33.Na-akpa | Na-eme mkpọtụ |

| 13 | Electrorating | 34.Electroplating Zn 35. Electroplating NICUNI 36.Phosphating 37. Chemical Ni | Electrolating Zn NICUNI Electrolating Phosphating ma ọ bụ Chemical Ni |

| 14 | Nyocha mkpuchi mkpuchi | 38.Ọkpụrụkpụ-39.Nguzogide nrụrụ-40. Adhesiveness-41.-Nleba anya nke ndidi | Ọkpụrụkpụ Nguzogide corrosion Nrapado Nyocha nke ndidi |

| 15 | Magnetization | 42.Nnyocha zuru oke- 43.Akara- 44.Nhazi/Mwelite- 45.Magnetizing | Nyocha zuru oke Ịka akara Nhazi/Mgbanwe Magnetization Nnwale magnetik Fiux |

| 16 | Nkwakọ ngwaahịa | 46. Igwe Igwe Ọdụdọ- 47.Bagging- 48. Nkwakọ ngwaahịa | Akpa Nkwakọ ngwaahịa |

Oge nzipu: Feb-15-2023